Failed Scheduling Analysis

This feature displays the full information about limitations found during a scheduling operation. The information is intended to help the user in deciding whether it is possible to find room for the order near the preferred date or if the order has to be moved.

The feature is available in the Reschedule Delivery Order dialog as well as the Reschedule Production Order dialog, when scheduling a single order manually with the automatic algorithm. It is activated by a checkbox “Display all Shortages”. It can also be activated from the Scheduling Result dialog when a scheduling operation has failed.

Please note that this feature checks ALL Planning Resources for ALL possible days. It is thus more time-consuming than a normal scheduling, which aborts after the first found shortage.

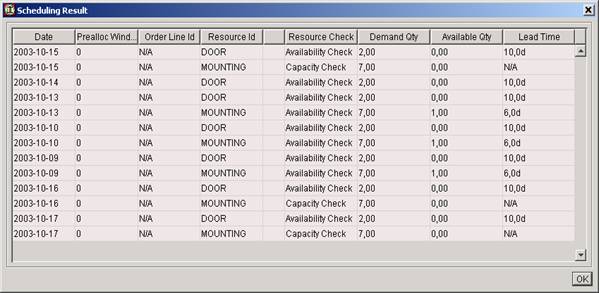

All found shortages are displayed in a grid dialog. In the example below, the preproduction window is 1 + 4 days and the forward scheduling window is 2 days. Order Line Id is not displayed if “Joint Scheduling”. The Available Qty refers to Capacity Limit minus orders if Capacity Check is used; else it refers to “Available Balance” (balance plus inbound deliveries minus outbound deliveries) minus orders. Available Qty may be negative e g if orders have been forced into the production plan. Lead Time is only significant if Availability Check.

If a Planning Resource allows preallocation, Preallocation Window differs from zero. Here the failure date reported is the production date of the order, though the test is performed in the full preallocation window. For preallocation a single Available Qty can not be presented. The same applies to Resource Check if “Availability and Capacity Check”.