Own Bucket Detail

The Own Bucket Detail screen contains all the information about a particular Bucket, i.e. your stock of a particular product (or Product Variant).

Product Id The Product Id and Product Variant is the identifier of a unique product in PipeChain Supply If possible, use the same ID (+ Variant) for the product in PipeChain Supply as in your ERP system.. The ID must be entered when the product is first created. It can consist of numbers and/or letters. Once the product information has been created and saved, the ID cannot be changed.

(Product) Variant The variant, in your PipeChain Supply, of the product. (Each has its own line in the list of products and its sown in Own Bucket Detail screen).

Product name The name, in your PipeChain Supply, of the product.. The Product Name field can be edited after the product data have been saved the first time.

Description - this field can contain comments that your company may wish to make about the product in question. The Description field can be edited after the product data have been saved the first time.

Exactly how to make use of the Description field is something that should be discussed at the time of installation with the application consultant responsible for the installation and configuration of PipeChain Supply.

Tabs

The Bucket tab contains information about the stock status of this product.

(Duration Meter) a graphical representation of the duration. See the Duration Meter section for further explanation of how the Duration Meter works.

Duration the time until your stock of this product (or Product Variant The variant, in your PipeChain Supply, of the product.) runs out. PipeChain Supply calculates the duration based on the Balance and Outflow Demand.

Stock In Transit the run-out time of the stock in transit of this product (deliveries confirmed by suppliers or in transit).

Balance the quantity of this product (or (Product) Variant) that you have in stock. When you first define the product in PipeChain Supply, you enter the balance manually. The balance can then be modified manually or by an external system.

Shortage reflect negative balance if used. The shortage value is coming from transaction Product Balance. The shortage value can also be corrected manually in Own Bucket Overview/Detail screen. The shortage will be adjusted before balance at goods reception.

Virtual Balance your stock balance of this product, plus the quantity contained in current inbound deliveries of this product minus shortage. The virtual balance is calculated by PipeChain Supply.

Critical Time , Lead Time, Safety Time , Max Time these values are set by the supplier in the inbound delivery agreement. If more than one supplier is supplying this product or Product Variant, the Critical Time, Lead Time , Safety Time and Max Time shown here are an average of the values in all of the delivery agreements.

Unit this field specifies the unit in which the quantity of the product is given: pcs, kg, etc.

Handle as Integer if this box is checked, the quantity of the product is always given as an integer (no decimals).

Outflow Demand & /workday your outflow (your sales, or what you use in your own production) of the product per day. PipeChain Supply calculates this value every night based on actual withdrawals of stock. You can also change it manually if there is a noticeable change in outflow.

Outflow Sensitivity the Outflow Sensitivity should be between 0.03 and 0.1. The higher the sensitivity, the quicker PipeChain Supply will adjust the outflow value to actual reductions in stock balance. If sales are usually constant, you can have a high level of sensibility, but if sales normally fluctuate a lot, it may be better to set a low level of outflow sensitivity to keep the outflow steady.

Balance Updated the date and time when the Balance was last updated.

Outflow Updated the date and time when the Outflow Demand value was last updated.

Real Outflow - Shows the real outflow for this product at a certain time when the snapshot is taken. It is done by a bakgroundsjob.

Real Outflow Date - The date and time when the real outflow was last updated.

There Is a Flow Model for This Bucket/No Flow Model Is Used for This Bucket if the text says that there is a Flow Model, you can click on it to open the Own Flow Model Detail screen, where you can view or edit that Flow Model.

If a Flow Model is used for this product (or Product Variant), this tab shows the Flow Model graphically. If no Flow Model is defined for the product, the Flow Meter value is shown.

For more information, see the Own Flow Model Detail screen, The Flow Model Tab.

+ The In. Deliv. Agreement Tab

Her you can se all inbound delivery agreements for this product. See more information below if you have one supplier or more supplier on same product.

If you have only one supplier of this product, the Delivery Agreement tab shows you the details of the delivery agreement you have with that supplier.

Supplier Id This (Supplier Id + Address) is what identifies the supplier in your PipeChain Supply: If possible, use the same ID (+ Address) for the supplier in PipeChain Supply as in your purchase/ERP system.. If you click on the underlined blue text, you open the Supplier Detail screen, where you can view or edit the information about the supplier.

Strategy this list box displays which replenishment strategy is used in this delivery agreement. There are two strategies, Bucket and Transport.

Compensate for Backlog During Lead Time .

Supplier Managed Inventory If the checkbox is checked, the delivery agreement uses SMI (supplier managed inventory). The supplier is in charge of confirming the suggestions and thus deciding delivery time and quantity. If the checkbox is not checked, SMI is not used, which means that the customer needs to place an order or confirm PipeChain's suggestions whenever the customer needs more of the product..

Critical Time The stock level you want your duration meter to turn red at. Should, if used, be considerably less than the Safety Time (or else your meter will never be yellow since the duration meter is turning red directly after is has been green). We strongly recommend the usage of Critical Time. If left undefined, the Lead Time will be used as Critical Time. This could be the time it takes 1/ to get goods from another supplier, 2/ to receive an express delivery or 3/ to reschedule the production..

Lead Time The time it takes from the moment the supplier ships the delivery in PipeChain Supply until it is received, registered and shows up in the customer's stock balance. The Lead Time is only used if Reception Time of the Reception Schedule is of Reception Days "type". If it is not, then the Lead Time is only for information purposes..

Safety Time The minimum stock cover time for which you want to have a stock of this product. You decide what the Safety Time should be based on the stability of deliveries and sales, and on the quality of the information covering balance and demand..

Max Time The maximum stock cover time you want to have stock of a certain product..

Safety Balance The fixed quantity below which you do not want the stock balance of the product to fall, even if there is no demand of the product. The safety balance overrides the Safety Time. By setting a Safety Balance you make sure that you always have a certain quantity in stock..

Max Balance Is a fixed quantity above which your stock balance of the product must not rise, no matter what the outflow is. The Max Balance overrides the Max Time. Example: a tank that can hold only 1000 liters cannot stock any more liters..

Multi Unit Quantity The checkbox is checked if the product is delivered in units of more than one product (e.g. pallet or case). The quantity of the product contained in each multi unit is specified in the field to the right of the checkbox. Delivery quantities are always rounded upwards to the nearest multi unit..

Reception Schedule Id The Id of the Reception Schedule..

If you have more than one supplier of this product, the Delivery Agreement tab displays a list of the delivery agreements with the suppliers. The tab then looks as below:

If you double-click on a row in the list, you open the Inbound Delivery Agreement Detail screen, where you can view the details of that delivery agreement. For explanations of the fields in the list that are not covered below, see the description of that screen.

Period Length decides the length of the period for which withdrawals from each suppliers share of your stock are summed up. There are two options: one day or one week. The period length only needs to be used if you also set a constraint for one of the suppliers. If you usually have more than one day between deliveries, you should choose a period length of one week, if you have less than one day between deliveries choose a period of only one day.

Last reset was the time shown here is the beginning of the current period.

Next reset is the time shown here is the beginning of the next period.

Update Share & when you want to change the replenishment shares of the suppliers, you click this button. The following dialog box opens:

Enter the correct shares and click OK. The Share (%) field is now updated.

Prepare For Extra Delivery you click this button if a supplier is unable to deliver as much as intended, and you want to let another supplier deliver more than their normal share. The following dialog box opens:

Fill out the fields and click OK.

Share (%) this field shows the suppliers share of replenishing your stock of the product. To change the share, click the Update Share button (see No. 4 above).

Constraint in this field, you specify if the supplier has any upper or lower limit to how much they can deliver. There are three possibilities: None if no limit is set, Max if there is a maximum limit and Min if there is a minimum limit. If you click in the field, you can choose one of the three options from a list box.

Note Only one supplier can have a constraint on each product.

Constraint Quantity if you have chosen Max or Min in the Constraint field you must specify the maximum or minimum quantity in this field.

If you right-click on a row in the list of Delivery Agreements, you open a menu where you can choose the following commands:

Sort By: Opens a submenu where you can choose how to sort the list items.

Analyze: If you choose this command, PipeChain Supply analyzes the agreement to see if the values are well adapted to the customers actual outflow etc. The result is shown in a dialog box as soon as the analysis is complete.

Generate Inbound Delivery Suggestion: If you choose this command, you create an inbound delivery suggestion for this product. The button is only enabled if inbound delivery suggestions are allowed for the supplier in question.

Delete Suggestions if you click on this button, you will delete all inbound suggestions for this product.

Set Inventory Responsible - if you choose this command, you can change the responsible part for the Inventory. See below figure.

Send Delivery Forecast sends a delivery forecast for this products and site to the supplier (CS67).

Generate Inbound Delivery Suggestion if you click on this button, you create inbound delivery suggestions for this product. The button is only enabled if inbound delivery suggestions are allowed for the delivery agreement in question.

Delete Suggestions if you click on this button, you will delete all inbound suggestions for this product.

Send Delivery Forecast sends a delivery forecast for this products and site to the supplier (CS67).

Generate Inbound Delivery Suggestion if you click on this button, you create inbound delivery suggestions for this product. The button is only enabled for non-SMI products and if inbound delivery suggestions are allowed for the delivery agreement in question.

The Inbound Deliveries tab shows deliveries of this product that have been announced by the supplier(s).

If you double-click on a delivery row, you open the Inbound Delivery Detail screen for that delivery.

The Receipt Time The planned, confirmed or actual Reception Time of this delivery. field turns yellow if the delivery has been shipped but not received, and the receipt time is in the past.

If you right-click on a row in the list of inbound deliveries, you open a menu where you can choose the following commands:

Sort By opens a submenu where you can choose how to sort the list items.

Recalculate - Recalculates the shipment and receipt time for the delivery suggestion. The command is only enabled if the status of the inbound delivery is suggestion.

Change Time - Shows a dialog where the Shipment Time and Receipt Time for a delivery can be changed.

Generate Order - Creates a Purchase Order An order created by: - PipeChain if it concearns a delivery from a supplier to your PipeChain, or - your purchase/ERP system (or manually by PipeChain) if it concearns a delivery from a supplier to your PipeChain, or - the customer's purchase/ERP system, if it concearns a delivery from your PipeChain to a customer.. The order will list the delivery suggestion you right-clicked on, plus all other suggestions with the same shipment time The planned, confirmed or actual Shipment Time of this delivery. or belonging to the same blanket order The blanket order is a reference used to identify the customer's purchase order.The blanket order reference can be used to make goods receipts. The blanket orderreference is normally created in the customer's order system and sent to PipeChain,or entered manually. (depending on the setting under Replenishment Order A VMI order generated by PipeChain. in the Own Business screen and Order Generating Strategy in the Supplier Detail screen. The command is only enabled if the status of the inbound delivery is suggestion.

Add to Order - Adds the selected delivery suggestion to an order. The command is only enabled if the status of the inbound delivery is suggestion.

Remove from Order - Removes the selected delivery suggestion from the order to which it belongs. The command is only enabled if the status of the inbound delivery is suggestion and the suggestion is tied to an order.

Confirm - Confirms the delivery suggestion. The command is only enabled if the status of the inbound delivery is suggestion and the suggestion is tied to an order.

Allow Order Change - Defines if the order may be changed or not.

Register Reception registers that you have received all or part of the quantity of the delivery. This command has the same function as the Register Reception button in the Inbound Delivery Detail screen. See page 57 for a detailed explanation of the function.

Cancel Delivery - this command is used to cancel the delivery suggestion manually.

Inventory Chart - Opens the Inventory Chart for this Supplier / Product. Note that the current delivery's Receipt Time is "marked" in the Closing Inventory Chart with the date bold and in the Continuous Chart with a faded blue line.

Show Notes - Opens the Notes window if there are any Notes for this delivery.

The Shipment Time field turns yellow if the delivery has not been shipped yet and the shipment time is in the past.

The Customer Buckets tab displays all Customer buckets that are linked to this product via the Outbound Deliver Agreement.

Double-clicking on a row will take you to the Customer Bucket Detail screen for this Customer Bucket.

Right-clicking on a row shows a menu where you can:

Sort By - Opens a submenu where you can choose how to sort the list items.

Recalculate Duration - If you use this command, PipeChain Supply will show the precise duration of this customer bucket as of this moment. The duration is always recalculated automatically at night.

Generate Delivery Suggestion - If you choose this command, a new delivery suggestion will be created for this product and customer, and the Outbound Delivery Suggestion Detail screen will be opened.

Inventory Chart if you click this button, you open an Inventory Chart for this customer bucket.

The Outbound Deliveries tab shows deliveries of this product from you to your customers that you have announced (i.e. you have confirmed the delivery suggestion). If you double-click on a delivery row, you open the Outbound Delivery Detail screen, where you can view the details of that delivery.

Note If

you delete an outbound delivery, and a data exchange has already

been made after that outbound delivery was created, you have to inform

the customer so that they can delete the corresponding inbound delivery

in their PipeChain Supply.

The recommended procedure to delete an outbound delivery is to cancel/remove

it not to delete

it.

The Shipment Time field turns yellow if the delivery has not been shipped yet and the shipment time is in the past.

The Receipt Time The planned, confirmed or actual Reception Time of this delivery. field turns yellow if the delivery has been shipped but not received, and the receipt time is in the past.

If you right-click on a row in the list of inbound deliveries, you open a menu where you can choose the following commands:

Sort By opens a submenu where you can choose how to sort the list items.

Recalculate if the status of the delivery is Suggestion, this command recalculates the shipment time and quantity for the delivery suggestion based on a new receipt time which you enter.

Generate Order creates a Replenishment Order A VMI order generated by PipeChain. that includes the selected outbound delivery.

Confirm - Confirms the delivery suggestion.

Confirm Changes - If the customer has change there order (WebShop) can the supplier confirm the order if status on order is Changes Sent or Change.

Ship Delivery - Registers that the delivery has been shipped.

Cancel Delivery - Cancels the delivery before shipment.

Inventory Chart - Opens the Inventory Chart for this Customer / Product. Note that the current delivery's Receipt Time is "marked" in the Closing Inventory Chart with the date bold and in the Continuous Chart with a faded blue line.

Change Own Product - Opens a dialog where you can choose to deliver another own (replacement) product instead of the suggested product.

Allow Order Change - Defines if the order may be changed or not.

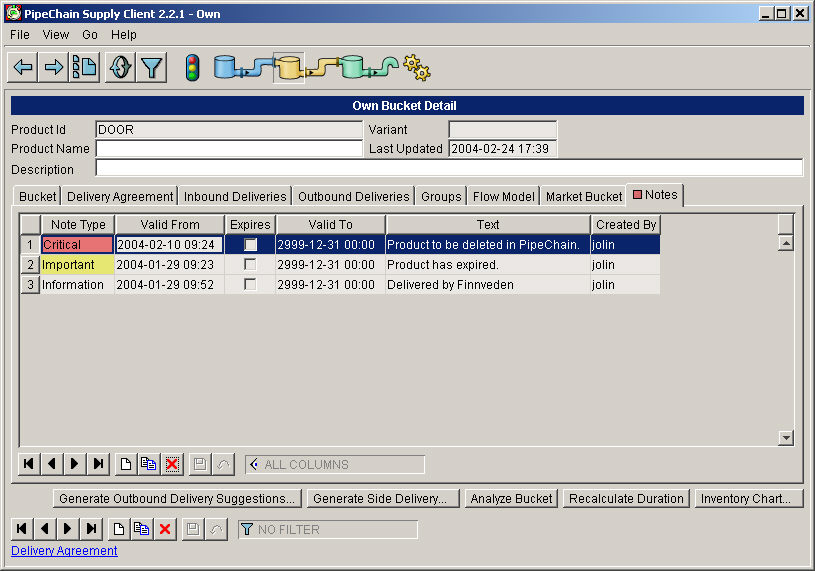

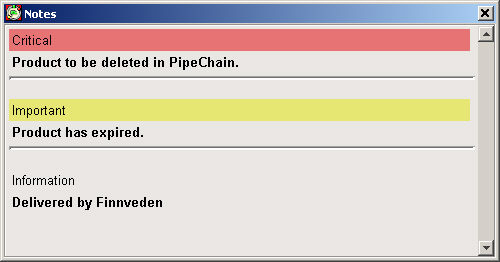

The Notes tab contains information about notes for this product.

The active notes for a product can be viewed in the Own Bucket Overview screen (by right-clicking and choosing "Show Notes") and in Own Bucket Duration Meters (by clicking the "Notes" button). This action will open a Notes window for the product.

A Note added by a user can only be edited and deleted by the user and by a system administrator.

There can be more than one Note on a product.

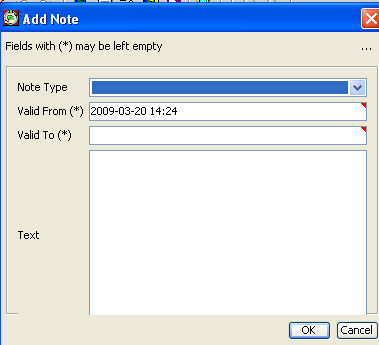

To add a new note:

Note Type - The importance of the note. It can be Information (no color), Important (yellow) and Critical (red).

Valid From - The date when the note becomes active, i.e. it is shown in other screens and colors the Notes Tab square.

Expires - checkbox that the Note will expire at some point in time

Valid To - The date when the note will expire and be automatically deleted from the system

Text - The information of the Note.

Created By - User Id of the user who created this Note.

Total Stock in Supply Chain displays the how much stock is known to PipeChain, where it is located (Confirmed Inbound, Shipped Inbound, Own Available, Outbound Confirmed, Outbound Shipped and at Customer locations) and the estimated number of days it will last, including the date and time when the stock is estimated to reach zero stock level and go below the zero stock level. The tab is available in all segments.

The Market Bucket shows the information about your Market Bucket, i.e. what the stock and outflow demand (the sum of all buckets) adds up to in the entire supply chain all your customers, their customers, and so on. This allows you to prepare for changes in demand from customers in good time. Your own product bucket is included in the Market Bucket.

Fill Rate the fill rate is a percentage that shows how well the supply chain ahead (downstream) of you is meeting the demand for the product. The Market Meter (A) visually presents the market buckets fill rate.

If the fill rate is 0% the quantity of goods in the supply chain is just enough to last the Safety Time + the Lead Time .

If the fill rate is below 0%, the quantity of goods in the supply chain is not enough to last the Safety Time + the Lead Time.

If the fill rate is 100%, the quantity of goods in the supply chain is at a desirable level.

If the fill rate is above 200%, the quantity of goods in the supply chain is enough to last for more than the maximum time + the Lead Time.

Market Meter the Market Meter visually presents the market buckets fill rate (No. 1).

The Market Meter is

red when the quantity of goods in the supply chain is not enough to last the Lead Time.

yellow when the fill rate is less than 0%, but the quantity of goods in the supply chain is enough to last for more than the Lead Time.

green when the fill rate is between 0% and 200%.

blue when the fill rate is above 200%.

Time The accumulated run-out time relative to the preferred time. This value tells you how critical the situation is with this product and helps you prioritize. It is negative if the fill rate (No. 1) is below 100%.

Balance: The total stock balance relative to the preferred balance. This value tells you how much of this product you need to produce or order. It is negative if the fill rate (No. 1) is below 100%.

Lead Time the Lead Time of the Market Bucket is the sum of the Lead Times set in all the delivery agreements for this product by you, your customers and all customers ahead in the supply chain.

Example If there are 9 customers ahead of you in the supply chain, and you and they each have a Lead Time of 1 day, then the Lead Time of the Market Bucket is 10 days.

Safety Time the Safety Time of the Market Bucket is the sum of the Safety Times set in delivery agreements for this product by you, your customers and all customers ahead in the supply chain.

Example If there are 9 customers ahead of you in the supply chain, and you and they each have a Safety Time of 2 days, then the Safety Time of the Market Bucket is 20 days.

Pref Time this is what the duration (see No. 9 below) of your Market Bucket should be, according to PipeChain Supply. The preferred time is based on the Safety Time, the Max Time and the Lead Time.

Max Time the Max Time of the Market Bucket is the sum of the Max Times set in delivery agreements for this product by you, your customers and all customers ahead in the supply chain.

Example If there are 9 customers ahead of you in the supply chain, and you and they each have a Max Time of 10 days, then the Max Time of the Market Bucket is 100 days.

Duration the total duration of the stock of the product that you, your customers and all customers ahead in the supply chain have. Duration is stock level expressed in run-out time (we have enough of the product for so and so many days).

Lead Time Balance the Lead Time Balance is the quantity of the product that is needed to last for the Lead Time of the Market Bucket (see No. 5 above).

Example If the outflow of the product is 10 pcs per day, and the Lead Time of the Market Bucket is 10 days, then the Lead Time Balance is 100 pcs.

Safety Balance the Safety Balance is the quantity of the product that is needed to last for the Safety Time of the Market Bucket (see No. 6 above).

Example If the outflow of the product is 10 pcs per day, and the Safety Time of the Market Bucket is 20 days, then the Safety Balance of the Market Bucket is 200 pcs.

Pref Balance this is what the balance (see No. 14 below) of your Market Bucket should be, according to PipeChain Supply. The preferred balance is based on the Safety Balance, the Max Balance and the Lead Time Balance.

Max Balance the Max Balance is the quantity of the product that is needed to last for the Max Time of the Market Bucket (see No. 8 above).

Example If the outflow of the product is 10 pcs per day, and the Max Time of the Market Bucket is 100 days, then the Max Balance of the Market Bucket is 1000 pcs.

Balance the total quantity of the stock of the product that you, your customers and all customers ahead in the supply chain have.

Outflow the total outflow (sales or use) per day of this product of your customers plus all the customers ahead in the supply chain.

Updated the time and day when the Market Bucket data were last updated. (Market bucket information is transferred when a Normal Exchange takes place).

Update if you click this button, the Market Bucket data are recalculated immediately without waiting for the next data exchange.

In this tab, the product can be added to one or more product groups. The purpose of this is so that each user will be able to set the filter to show only those products he or she wants to work with.

The left-hand field shows a list of all existing product groups where the product is not a member. The right-hand field shows all the groups where the product is a member.

Add the product to a group by moving the group ID from the left field to the right, using the buttons between the fields.

The groups are created in the Product Group Detail screen. If you want to add more than one product to the same group, you can do it in that screen.

In the Delivery Units Tab the Delivery Units are defined, and the amount of quantity of the product that goes on each Delivery Unit.

You can specify more than one Delivery Unit for a product, like Carton, Layer on Pallet, Half Pallet and Pallet.

The Delivery Units are used to define the standard Delivery Unit in the Delivery Agreements and are used in the Load Planner for Load Optimization.

The Delivery Units are also used to define the Unit of Measure in the Delivery Agreements for conversion supplier units, if it is different.

You will be able to see the number of Delivery Units in the Delivery (Suggestion) screens.

Only used when using the WebShop Module.

In this screen you can enter related products.

+ The Alternative Sourcing Tab

This tab contains information about the product's availability on all sites. There are no use cases for moving data or changing orders, just information that enables analysis.

For each site, the balance and duration is shown.

Then the Partner Id, Transport Leadtime, Production Leadtime and Confirmation Margin for the supplier (in case of multiple suppliers - the one with the shortest combined leadtime).

Then the (announced) Reception time for the latest inbound delivery (confirmed but not received).

The combination of the above parameters control the period of the Inventory Analysis, which is also presented.

From the Inventory Analysis the following parameters are extracted:

- Available Balance - i e the lowest occurring balance during the analysis.

- Total Inbound delivery quantity during analysis

- Total Requirement (outbound deliveries) during analysis

- Final Balance and Duration at the end of the analysis

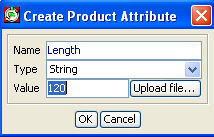

In this tab can you add attribute to the product.

If checkbox Is WebShop Product checked the product will be showed in WebShop.

Creating Product Attribute: Click new item for creating product attribute. Fill in name, type (could be a pdf file, document, string, url.

Click upload file button for upload a file for this product. Is used in WebShop.

In the Consignment Tab you find information about the Consignment consumption lines displayed for this product.

Transaction CS04 Inventory Report is extended to also report consignment consumption. Consumption lines stored in Inventory Activity can be forwarded to the supplier in a transaction PW55 Consumption Report. The scheduling of sending PW55 is configured in screen Inbound Partner Agreement tab Advanced. The scheduling is done by a calendar, the report will be sent on all open days in the calendar and the time is determined by a new field. A supplier can have both consignment products and none consignment products. A product can be activated as a consignment product in check box "Use Consignment Stock". This check box is found in Inbound Delivery Agreement tab Advanced.

Multi Source

A product can have several consignment suppliers it can also have both consignment suppliers and none consignment suppliers.

For a consignment product is all balance updates logged in the InvActivity table. There are 5 types of activities

1. Consignment Consumption

2. Consignment Correction

3. Delivery Receipt

4. Cancel Delivery Receipt

5. Inventory Adjustment

It possible to correct Consignment Balance with a button "Correct Consignment Balance" in a new tab Consignment in screen Inbound Delivery Agreement.

It possible to send PW55 Consumption Report manually for a certain product. This is done with a new button "Send Consumption Report" in the new tab Consignment in screen Inbound Delivery Agreement

In the Consignment Tab you find information about the Consignment consumption lines displayed for this product.

Requirements for Consignment in PipeChain is that the ERP system at customer side must be able to send consumption report for each consignment supplier and that the supplier must be able to register a ’warehouse’ (Location Id) in his system to represent each customer’s consignment stock.

- Current Balance Ownership -

Actual balance is showed as partial balance and balance/owner. Partial balance is the same as your bucket partial balance showing in the bucket tab.

- Inventory Activity -

Here you find detailed information about the consumption lines.

5 types of Inventory Activities

Consignment Consumption (Affect Consign Balance)

Consignment Correction (Affect Consign Balance)

Delivery Receipt (Affect both Partial & Consign Balance)

Cancel Delivery Receipt (Affect both…)

Inventory Adjustment (Affect Partial Balance)

3 types of references

Reference Used for i.e. batch number

Location Id Warehouse Id for consignment goods

Purchase Order Id Used order for this consignment consumption. Videlity is using Purchase orders

References could be fetched from inside PipeChain or applied in CS04 transaction

- Reports -

Some of the measures PipeChain Analyzer offer, such as Tied-up Capital and Volume Value Weighted averages require that each product is assigned volume and standard cost data. PipeChain Supply handles monetary units in several ways, but PipeChain Analyzer retrieves this data exclusively from the table OwnProdNode, columns Volume, Value and VolumeValue. Volume may be a sales or demand forecast. The attributes are visible in the report tab as Volume, StandardCost and VolumeValue.

The data is editable in the above screen, but should normally be updated by the Own Product Definition transaction (CS08).

The attributes are saved with each Inventory and Shipment history record, but there are Pivot Table KPIs only for Inventory.

Buttons

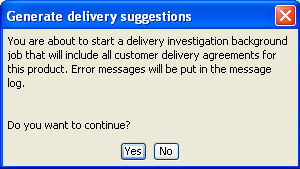

Generate Outbound Delivery Suggestions... - with this button, you can create new delivery suggestions for this product for all customers, at any time. Your PipeChain Supply generates delivery suggestions for all products after every time a data exchange has taken place with a customer.

When you click the button, the following dialog opens:

If you click Yes, PipeChain Supply will begin creating delivery suggestions for the product in question.

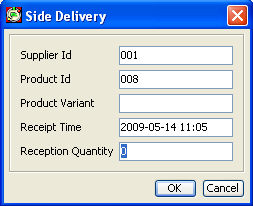

Generate Side Delivery... - use this button when you have received or purchased a quantity of the product that was not announced as a delivery in PipeChain. It is important to register such goods, otherwise PipeChain Supply will be calculating your outflow based on incorrect information.

When you click the button, the following dialog box opens. Fill in the correct information and confirm by clicking OK.

You can enter a Supplier Id that is not registered in your PipeChain Supply, if you purchased the goods from an occasional source. However, if you purchase goods regularly from one source, you should register it as a supplier in PipeChain Supply.

Analyze Bucket - if you click this button, PipeChain Supply will check if your outflow of this product is adequate and inform you of the result in a dialog box:

If the message is that your outflow needs adjusting, change the value in the Outflow Demand field.

Recalculate Duration - use this button if you want PipeChain Supply to show the precise duration of this product bucket as of this moment. The duration is always recalculated automatically at night.

Inventory Chart - if you click this button, you open an Inventory Chart for this product.