How to Reach Maximum Supply Chain Connectivity & Proactivity

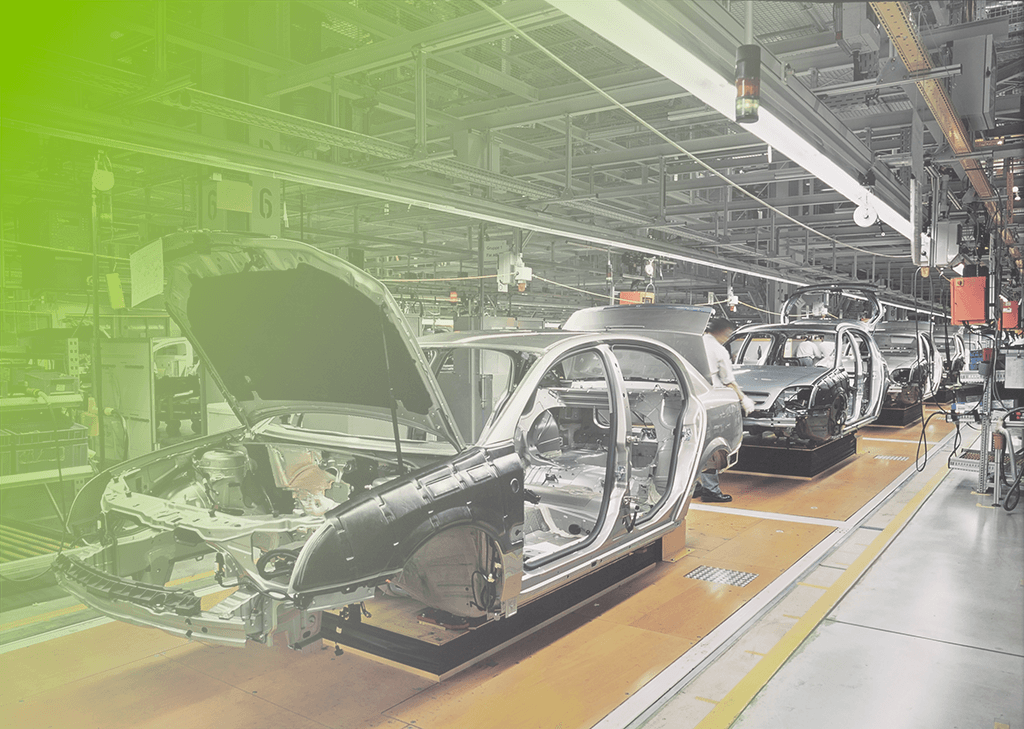

The lack of order status creates delays and unnecessary costs in the supply chain. Most companies are mature enough in their supply planning to address this challenge, and yet we can see many companies still focused on big ERP projects and prioritizing “within their four walls” improvement projects. A lot of value can easily be created, without huge investments and projects that stretch over many years, by focusing on maximum supplier connectivity as a service. This will enable you to move from a Reactive mode to an Anticipating and Collaborating mode – within your current system set-up.

First, control and consolidate your global inbound orders and deliveries as a foundation for your supply chain visibility. This can be achieved multi-site within your ERP infrastructure. Visibility and insight into the order and transport flows give you control over the incoming deliveries. This creates the opportunity for you to:

- Decrease your buffer stocks

- Act before your problems occur or become very costly

- Work with correct staffing

- Minimize your manual follow-up

- Automatically get suppliers responses into your ERP system, e.g. delivery of goods and status of shipments

- Ensure that your suppliers work coherently and efficiently towards you

Secondly, improve your ability to respond to your customer requirements, with higher responsiveness in production plants and warehouses, by adding your own stock data and production plans, customer forecasts, and a set of flow parameters into a shared visibility dashboard. Understand important fundamentals such as:

- If supply meets demand

- If you are at risk in terms of shortages, or if you are overstocked

- Where your time-critical supply chain problems are

- Where you should spend your dollars to improve your supply chain

Read our Automotive Tech Papers

Insights

If you are interested in learning more about how to create a powerful connected supply chain, here are our latest insights.

Tech papers

To help you get a deeper and better understanding of our solutions and your supply chain, we have developed a number of detailed tech papers on different subjects.

-

Necessary

These cookies are not optional. They are needed for the website to function. -

Statistics

In order for us to improve the website's functionality and structure, based on how the website is used. -

Experience

In order for our website to perform as well as possible during your visit. If you refuse these cookies, some functionality will disappear from the website. -

Marketing

By sharing your interests and behavior as you visit our site, you increase the chance of seeing personalized content and offers.