Succeeding in digitalization through spread

No good (digitalization) deed gone unpunished

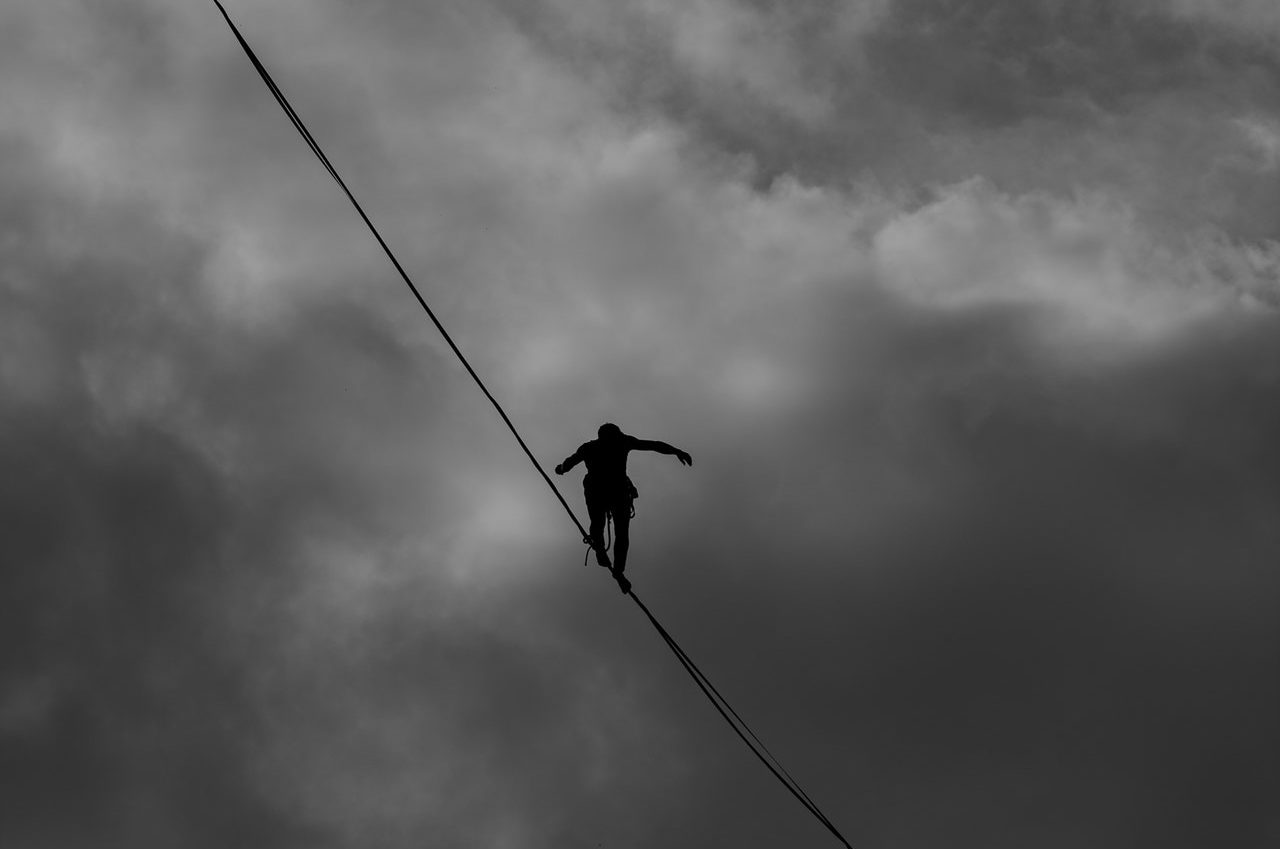

There are few things that are as frustrating as a half-finished project. Like a house where only one side has been repainted. Not only is it a testament to your inability to finish the project. It is also material, technology, time, energy and of course pride that has been invested, but not utilized. Those working with supply chain digitalization initiatives will recognize this horrible feeling.

Too often are initiatives for process-improvements and IT-support not reaching enough spread. It’s something that happens for all types of companies, big and small. It is worth to note that reaching spread goals rarely means full spread, but instead intended spread. Namely the intended spread decided on based on the goals of the project.

But what causes digitalization initiatives to fail? These types of big initiatives are led professionally usually with technical and financial analysis before any action is taken. Furthermore, they are run and are driven by competent project management teams that have mandate to take measures if the project isn’t fulfilling its goals and intentions. Still, many profitable and competitive initiatives still halt during its process. The result is an investment in a process or IT-support but without realizing the intended payback. The answer we often receive is something in the lines of: “something else we had to prioritize came up” or “the process worked in theory but became a lot more complicated in practice”.

Reaching spread

The knowledge we can draw out from this can be divided up in four parts. Firstly, when it comes to these types of initiatives, thoughts about its “spread” needs to be addressed far earlier in the initiative process. Plan and act to make sure changes are done in the planning phase, instead of the action phase.

Secondly, middle-sized and large companies need to further their efforts in supporting the bottom-lines process changes and IT initiatives. Here even small increase in clarity and effort can make a large difference.

Third, remember to concretely visualize the current status compared to the final goal or intent of the digitalization project.

And finally, think outside the box. Everything doesn’t have to be within the borders of the current ERP. Specialized IT-systems capable of integration with other systems can greatly increase the possibility of success.

Changes are in the end usually done with difficulty and often don’t end up exactly the way it was planned. And as we can tell, this is especially true when it comes to digitalization projects.

Insights

If you are interested in learning more about how to create a powerful connected supply chain, here are our latest insights.

Tech papers

To help you get a deeper and better understanding of our solutions and your supply chain, we have developed a number of detailed tech papers on different subjects.

-

Necessary

These cookies are not optional. They are needed for the website to function. -

Statistics

In order for us to improve the website's functionality and structure, based on how the website is used. -

Experience

In order for our website to perform as well as possible during your visit. If you refuse these cookies, some functionality will disappear from the website. -

Marketing

By sharing your interests and behavior as you visit our site, you increase the chance of seeing personalized content and offers.