The connected and agile supply chain

BY AGNETA LUND

This article was originally published in Supply Chain Effect 5-24 (read the full magazine here).

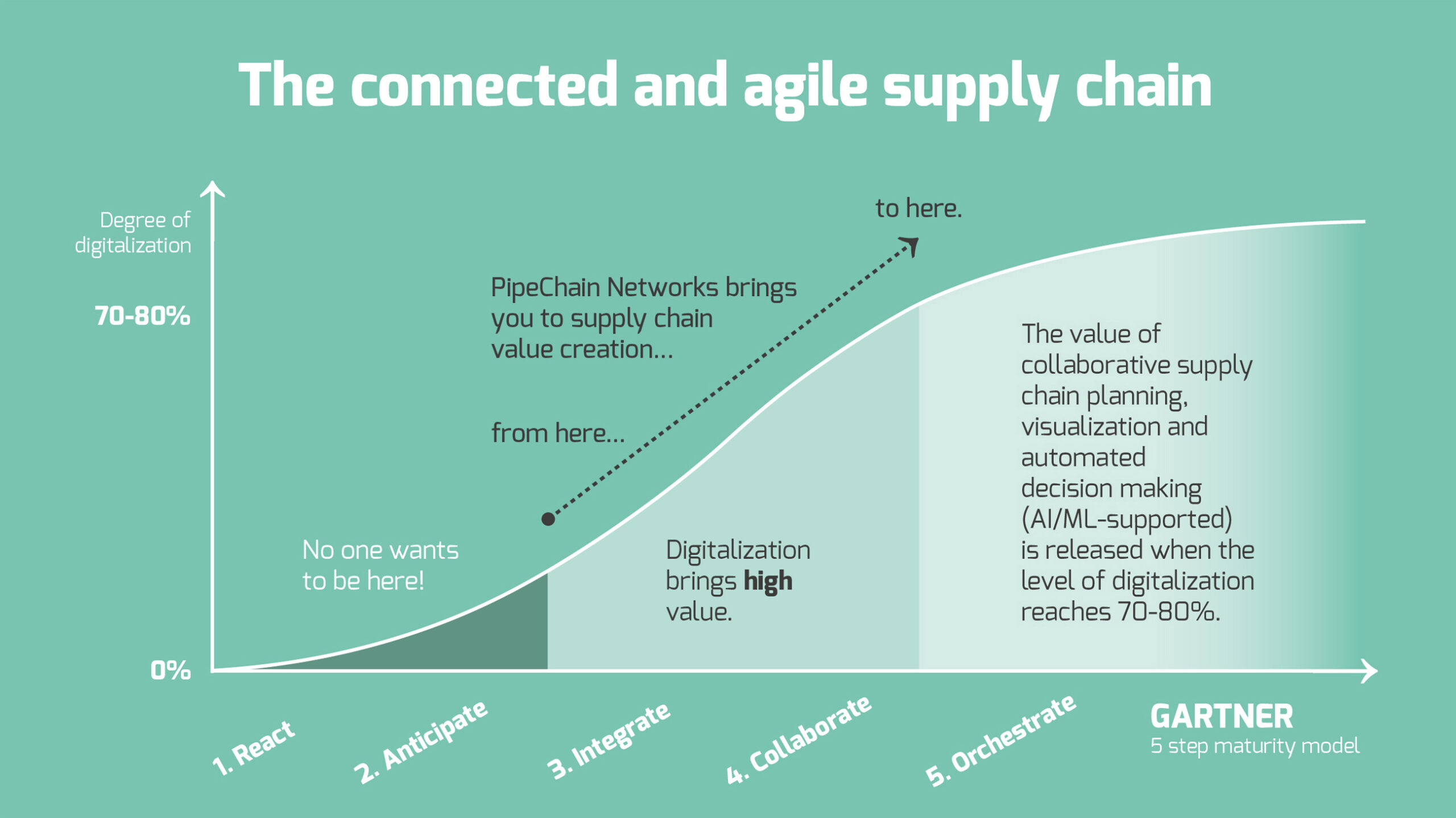

The path to the connected, agile and sustainable supply chain is first of all that it is connected. Namely, that the order process is digitized around 70-80 percent, end-to-end, before the truly large values can be realized.

With such a high level of digitization, many positive effects can be realized, typically: reduced inventory levels, minimized production disruptions, minimized inventory obsolescence, reduced costs for extra transport and personnel as well as a reduced need for administration for follow-up and control. It is when order flows are digitized, and the affected systems of all business partners are quickly and correctly updated that the journey towards value creation can begin.

Believed in revolution, but it became an evolution

When PipeChain was founded in 1999 and built its vision, it was automatic stock replenishment via so-called vendor managed inventory (VMI) that was supposed to revolutionize the world’s supply chains. A quarter of a century later, we see that it is rather an evolution, a gradual development, that still is going on. The evolution is driven by an increasing degree of digitized flows in supply chains, an increasing sharing of qualitative data, automated decisions, and incredibly much better conditions for working predictively with the help of advanced analysis and AI. But for this development to take place and create maximally good results, cooperation between the parties involved, supply chain collaboration, is also needed.

Gartner’s 5 step maturity model

In previous articles in Supply Chain Effect, we have referred to Gartner when describing this evolution. Gartner has long since also come to the same conclusion: that a company and its partners in the supply chain need to go through a maturation process in order to finally establish an efficient and truly value-creating supply chain.

This maturation process is illustrated in Gartner’s 5 step maturity model for supply chain (see figure). The various maturity phases in the model are summarized like this:

-

1. Reacting – Can I cover tomorrow’s order(s)?

2. Anticipating – Can I produce to the existing demand plan?

3. Integrating – How to integrate the logistics function into the overall supply chain?

4. Collaborating – Can my suppliers meet my business opportunities?

5. Orchestrating – How do I maximize revenue and profitability through an orchestrated demand response?

You cannot skip any of the steps

One of the key points of Gartner’s model is that you cannot jump straight into a higher maturity stage, you simply have to work your way through the phases step-by-step. According to our experience, this in step 1 to 3 is about digitizing to varying degrees. Moving from step 1 to step 2 may thus involve the largest customers and a few individual suppliers. Moving from step 2 to step 3 may be driven by either a pressure from your customers to digitize, or you yourself subjecting your suppliers to the same pressure. Stage 3 to stage 4 is a more comprehensive digitization that includes both customers, suppliers and carriers. Many times, either industry pressure is required – as in the global automotive industry, which can truly be said arrive at point 4 – or it is required that large companies that have the necessary decision-making and implementation power push through the necessary development that will take you from step 3 to step 4.

Agneta Lund, CEO, PipeChain Networks. Photo: Robert Lipic

EU directives and regulations

Directives and regulations from the EU in recent years are another thing that drives companies to move to the higher steps and perhaps even make many more quickly reach step 4 or step 5. Directives and regulations in sustainability place high demands on, among other traceability, climate footprint reporting and producers’ responsibility for packaging. In order to meet the sustainability requirements, more collaboration is needed throughout the supply chain, and even more digitization as well as a better utilization of already existing digitization. If, for example, a digital message already exists, it is more than reasonable to “reuse” this for the new data needed to meet the sustainability requirements.

Digitization is the basis for value creation

It is important to point out that the connected and agile supply chain starts with a high degree of digitization of the forecast, order, delivery and invoice processes, end-to-end, so that the business reaches Gartner’s step 4. After that, there is great opportunities to unlock the truly great values that creative collaborations and a demand-driven supply chain can create. Values that give the business a further strengthened competitiveness and profitability, a reduced climate footprint and, by extension, greater opportunities to establish completely new business models.

Insights

If you are interested in learning more about how to create a powerful connected supply chain, here are our latest insights.

Tech papers

To help you get a deeper and better understanding of our solutions and your supply chain, we have developed a number of detailed tech papers on different subjects.

-

Necessary

These cookies are not optional. They are needed for the website to function. -

Statistics

In order for us to improve the website's functionality and structure, based on how the website is used. -

Experience

In order for our website to perform as well as possible during your visit. If you refuse these cookies, some functionality will disappear from the website. -

Marketing

By sharing your interests and behavior as you visit our site, you increase the chance of seeing personalized content and offers.