The digitalized supply chain – an asset in a turbulent world

BY JULIA WELTMAN, MIKAEL JOHANSSON AND DANIEL TOLERGÅRD

This article was originally published in Supply Chain Effect 2-25 (read the full magazine here).

In a world characterized by uncertainty and rapid change, companies are facing challenges like never before. Increased tariffs, geopolitical tensions, strict EU regulations and intense competition in the automotive industry are just some of the factors affecting today’s business landscape. Amidst this turbulence, there is a vital asset and enabler: the digitalization of the supply chain.

By embracing digital solutions, companies can not only navigate through these challenges, but also strengthen their resilience and create a cost-effective and adaptable supply chain. The higher the degree of digitalization, the greater value can be created, which is often emphasized by experts, including Gartner’s supply chain experts.

Visibility, data sharing and complete delivery

We have extensive experience and in-depth knowledge in the automotive industry and retail, in particular. This is where our customers are, and this is where we can make the biggest difference. That said, we also need to be resilient and adaptable to be able to meet our customers’ challenges and expectations. One example is the transport company that we help to keep accurate stocks of items for delivery to Swedish manufacturing units. The goods are mostly components used to manufacture products in Sweden. Here, a subcontractor outside Europe is digitally connected to the transport company. Data about the goods that are stocked and in demand is shared seamlessly between subcontractors, the transport company and Swedish factories. By sharing data and using integrated applications, visibility, data sharing and ultimately a complete delivery are ensured.

Sustainability data is here to stay

Another example is how digitalization of the collection, sorting and analysis of sustainability data in the supply chain makes it possible to compile and report the sustainability data of items according to today’s rules and legal requirements. However, the insider knows that this only meets a fraction of the EU regulations and directives that have been decided recently. But this collection and analysis of sustainability data is an important part of all the sustainability data required in the EU. Although the EU has recently adjusted some of its requirements for the automotive industry, including how CO2 should be calculated to meet emission requirements, they have not been abandoned. Data still needs to be collected in the supply chain and used for calculations and monitoring. A sustainable, and smart idea is therefore to reuse the digital connections that already exist.

Daniel Tolergård, Julia Weltman and Mikael Johansson.

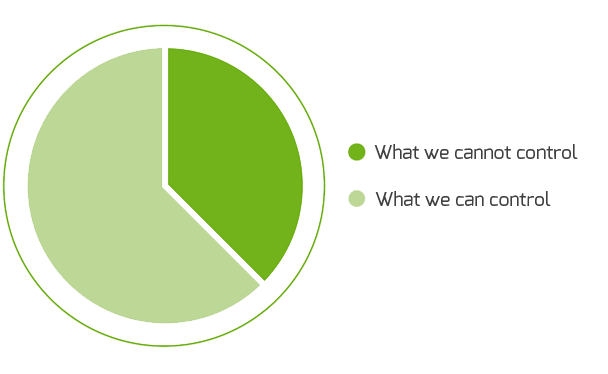

Dealing with the uncontrollable

Most often, changes are not about major disruptive changes such as tariffs and trade barriers, but rather about new requirements from large customers or suppliers. These requirements can mean adjustments in the supply chain, often in the digital realm. New standards, systems and approaches can require quick and flexible adjustments to avoid interruptions in production or deliveries. In our business, we have analyzed the markets we operate in and developed a working method that responds to the challenges and demands placed on adaptable digital supply chains. It is about being sustainable and resilient to be able to handle what we cannot control, and to deliver both smart digitalization and knowledge about supply chains and processes.

Cybersecurity and digital breaches

Being resilient and digitalizing your supply chain is also about cybersecurity and the risk of digital breaches. Supply chains in vital, socially important industries are typical targets for cyberattacks. Therefore, it is crucial for us that we are a well-equipped and reliable partner. By implementing robust security measures and continuously monitoring our systems, we minimize risks and ensure safe and efficient supply chains.

Julia Weltman is Key Account Manager at PipeChain Networks.

Mikael Johansson is Head of Partnerships at PipeChain Networks.

Daniel Tolergård is Head of Sales at PipeChain Networks.

Insights

If you are interested in learning more about how to create a powerful connected supply chain, here are our latest insights.

Tech papers

To help you get a deeper and better understanding of our solutions and your supply chain, we have developed a number of detailed tech papers on different subjects.

-

Necessary

These cookies are not optional. They are needed for the website to function. -

Statistics

In order for us to improve the website's functionality and structure, based on how the website is used. -

Experience

In order for our website to perform as well as possible during your visit. If you refuse these cookies, some functionality will disappear from the website. -

Marketing

By sharing your interests and behavior as you visit our site, you increase the chance of seeing personalized content and offers.