Hyperautomation in Supply Chains

Hyperautomation was named in 2019 by Gartner as one of the top 10 strategic technology trends in the world right now The concept of Hyperautomation is described by Gartner as the introduction of end-to-end automation that leverages the collaborative technologies of Robot Process Automation (RPA), intelligent business management software (iBMS), and machine learning and AI. The goal is to increase automated and AI-driven decision-making in more complex business processes that previously required human involvement.

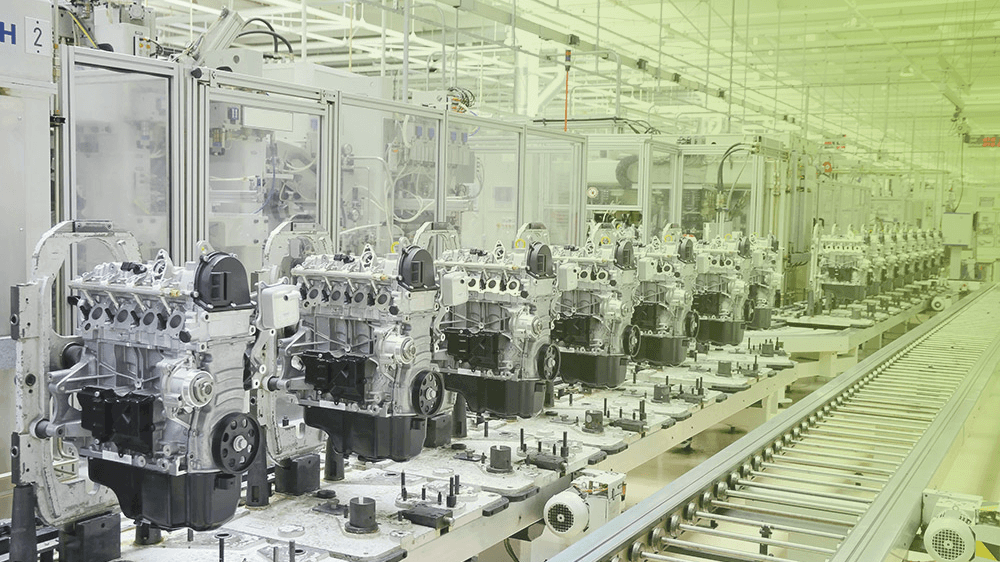

Here, I focus on Hyperautomation and its impact on human involvement in supply chains, at a time when connectivity is increasing, more and more processes are being digitized and large amounts of data are thus becoming available. Hyperautomation is then enabled in a number of processes, leading to parts of the work done by humans in both demand and supply management being automated using new technology and becoming machine-driven. In supply chain management-related software support, the new technology is mainly about AI and so-called Edge AI. Many “hypes” never become reality. I think Hyperautomation in supply chains will definitely become a reality. And the Automotive industry is well placed as a pilot.

Robot Process Automation with AI

Hyperautomation can become an engine for a broader transformation of human-involved processes to further automate more complex work that today requires knowledge input from humans. There is talk today of “Upskilling RPA* with intelligence” and that it creates the conditions for more advanced automation that not only replaces monotonous work, but is also able to take in data on an ongoing basis and assess the situation and act on it. Hyperautomation creates so-called Digital Workers that can connect to various process-critical applications, act on both structured and unstructured data, analyze data and make decisions, and also discover opportunities for further process improvement and automation capabilities. Combining RPA and AI technology thus creates opportunities to automate processes that were previously not possible to automate, i.e. non-documented processes that are partly based on unstructured data sets.

Automotive definitely has the potential to succeed

The automotive industry and the changes taking place there are favoring the development of initiatives such as hyperautomation. The industry is undergoing a fundamental change driven by digitalization, electrification, cloud computing and AI. Automotive executives are feeling these massive changes. In one of its recent reports, Accenture states that 75% of chief operating officers (“CXOs”) believe that the automotive industry will be completely transformed by new intelligent technologies. Another 60% believe, according to Accenture, that AI will be widely used in organizational processes. Half of CXOs also believe that the coexistence and collaboration between humans and machines is an important starting point for companies to achieve their strategic goals. My interpretation of the market situation is that new technologies will have a far greater impact on industry than traditional automation in manufacturing has. Not least because AI has the potential to affect entire supply chain flows and not just individual processes “within the four walls of the company”. This is likely to force automotive manufacturers in particular to transform their workforces, both in terms of training and how strategic developments are expected to affect the future of the companies. But is the workforce really ready? Are companies putting enough resources into training and retraining for the use of AI to support increased automation?

“People + Technology = Future strength”

Interestingly, Accenture highlights that the majority of automotive employees included in their various surveys believe that their jobs would be made easier by smart new technologies and encourage creativity and innovation. Personally, I think that’s true, but hyperautomation also reasonably implies that fewer people are needed in the processes involved. The jobs that remain will probably be both more interesting and more fulfilling.

Smarter technology leads to higher levels of digital integration and therefore better decisions

New smarter technologies are also opening the door to closer and more transparent collaboration in supply chains, while systems are increasingly integrated with each other. Companies’ data sources can thus be opened up to each other within reasonable limits and decisions can be made in a more cross-border manner, rather than within each legal entity. This, in itself, creates the conditions for new opportunities and, if we add AI, I believe we can take a leap, perhaps even a quantum leap, in terms of cross-border value creation in supply chains.

Hyperautomation with AI – seeing the forest for the trees

For many years, we at PipeChain, like many industry peers, have been working with KPIs and performance management in our software to help our customers see problems and possible sources of improvement. However, this type of KPI typically focuses on what has already happened. Instead, focusing our software support on what is happening here and now, or even better what is most likely to happen, increases the opportunities for both higher value creation and lower business risks and costs for our customers. The AI support pushes into this very issue and helps users to see the forest for the trees.

There’s still a lot to harvest and hyper-automation is helping

Today, companies are sharing and using data more than ever before, but the potential of this new wave of collaboration in supply chains is largely unrealized. The path to increased value creation through hyperautomation is to not grab too much at once. Instead, pick a sub-process, such as delivery schedules and deliveries in the automotive flow, and process both structured and unstructured data sets using AI, to make faster and smarter decisions. The gains will come from first-tier suppliers both understanding and responding better to OEMs’ needs. But also, that OEMs can get valuable feedback from their supply chain for improved quality of their own forecasts and thus more secure deliveries. The latter is a well-known and much debated problem, which has been the basis for industry initiatives based on KPIs such as the Forecast Accuracy Index (FAI). Finally, hyper-automation also creates opportunities for value creation at more than just the OEM and first-tier suppliers.

All this combined, makes me believe that hyperautomation is a hype that will become a reality!

* Robotic Process Automation, RPA, is also called Digital Associates and is about automating certain workflows, typically those that are repetitive, performed because some digital system is done with its task, is rule-driven without a lot of trade-offs or exceptions, feeds other digital systems (Wikipedia).

-Hans Berggren is CEO of PipeChain Group

Read more about how PipeChain can support the automotive industry here

Insights

If you are interested in learning more about how to create a powerful connected supply chain, here are our latest insights.

Tech papers

To help you get a deeper and better understanding of our solutions and your supply chain, we have developed a number of detailed tech papers on different subjects.

-

Necessary

These cookies are not optional. They are needed for the website to function. -

Statistics

In order for us to improve the website's functionality and structure, based on how the website is used. -

Experience

In order for our website to perform as well as possible during your visit. If you refuse these cookies, some functionality will disappear from the website. -

Marketing

By sharing your interests and behavior as you visit our site, you increase the chance of seeing personalized content and offers.